Furthermore, how do you calculate air leakage?

Calculate Air Leakage Rates

- Install an accurate absolute pressure vacuum gauge, measuring in Torr (mm Hg absolute).

- Calculate the total volume of the vacuum system in cubic feet.

- Pump down the system below the minimum required operating pressure.

- While the vacuum pump is running, close the inlet valve.

- Stop the vacuum pump.

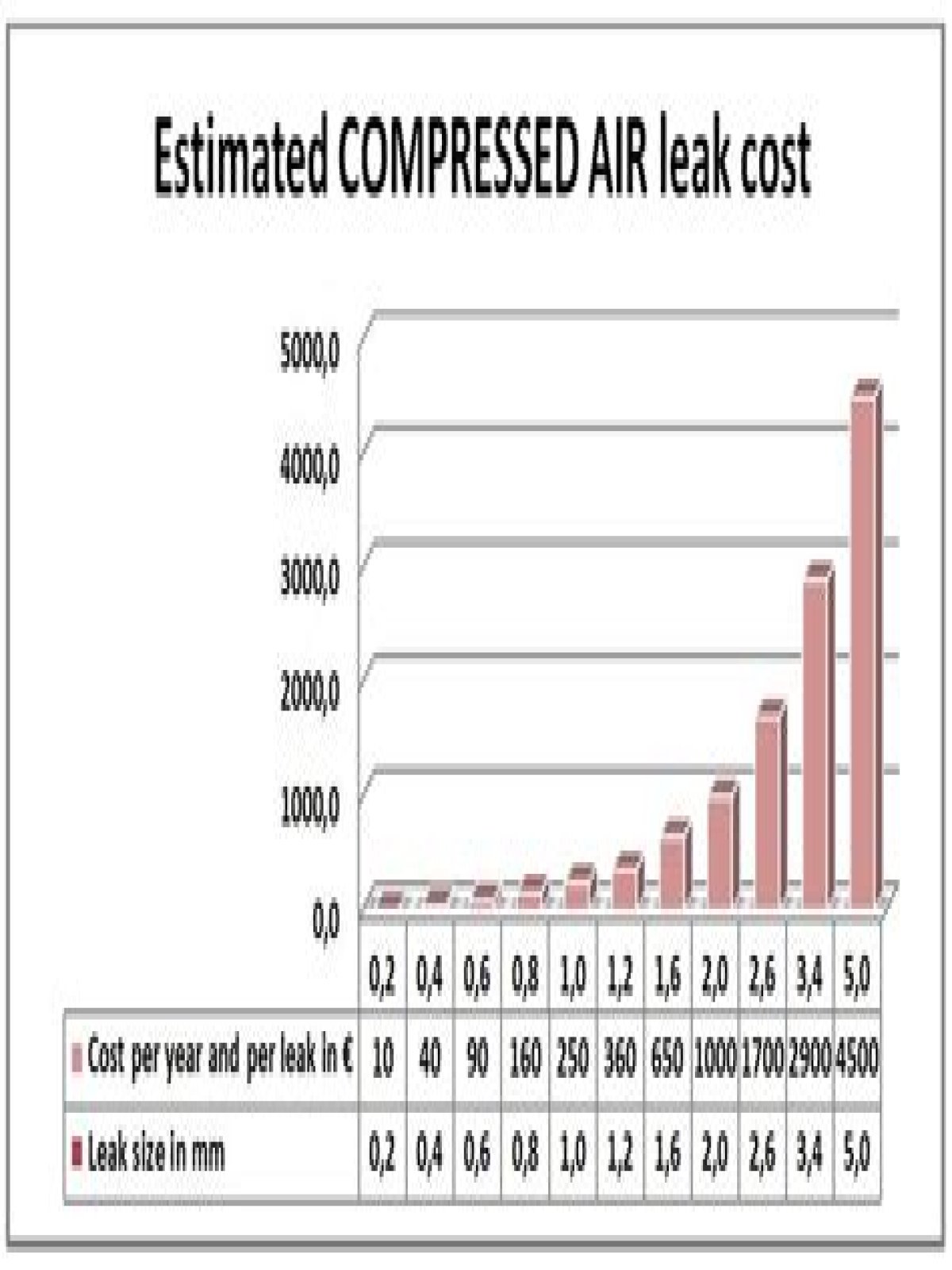

Subsequently, question is, what is the cost of compressed air per cfm? At $0.06 per kWhr, the estimated cost of compressed air is $0.02 per 100 cfm ($0.0002 per cubic foot). A 10 hp compressor delivering 35 cfm = $0.007/minute, $0.42/hour, $10.08/day, $302.40/month or $3,628.80/year.

In this way, how do you stop a compressed air leak?

Stopping leaks can be as simple as tightening a connection or as complex as replacing faulty equipment such as couplings, fittings, pipe sections, hoses, joints, drains, and traps. In many cases leaks are caused by bad or improperly applied thread sealant.

How do you check for a compressed air leak?

There are three commonly used methods of compressed air leak detection: listening/feeling, soapy water application, and ultrasonic.

- Leak Detection Method 1: Listening and Feeling.

- Leak Detection Method 2: Soapy Water.

- Leak Detection Method 3: Ultrasonic Leak Detection.

What is ach50?

What is a good blower door test result?

How much electricity does a air compressor use?

What is an ultrasonic leak detector?

How do you calculate CFM for compressed air?

How many CFM is a kW?

How do you calculate cfm of air flow?

Is compressed air expensive?

Do air compressors use a lot of electricity?

How do I know what power my compressor is?

- Compressibility factor (Z) = 0.9972.

- Molecular weight (MW) = 18.15.

- Gas constant (R) = 1544/molecular weight.

- Inlet temperature (T1) = 546 deg R.

- Inlet pressure (P1) = 15 psia (don't forget to use absolute pressure)

- Outlet pressure (P2) = 60 psia.

- K (Cp/Cv) = 1,274.

- Flow (W) = 0,184 lb/min.